Three Points That Must Be Considered When Choosing Wire containers

publisherMandy

time2020/05/13

- What factors should be paid attention to when purchasing storage wire containers? Do you know all this?

Three points that must be considered when choosing wire container

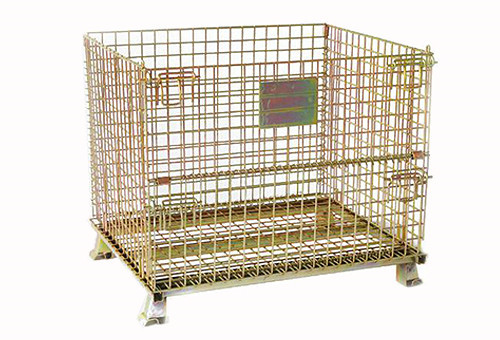

There are many factors that should be noted when choosing wire mesh cage. Below we will introduce a few places that we should pay special attention to. We hope that you must pay attention when choosing. As a tool for logistics turnover, storage cages can be said to be indispensable in the enterprise's storage field, but the purchase of storage cages is a question worth thingking about, otherwise, it is difficult to buy high-quality cages, let alone achieve three-dimensional management of cages too.

The shape and standard of storage items are directly related to the selection of steel cage standards. The weight of the storage items directly affects the strength of the storage cage, and the storage unit is the unit of storage. The pallet or the cage or the single product has different shelf selection types. There is also an estimate of the number of total reserves. It is necessary to take into account the company's growth needs in the next two years.

There are various surface treatment methods for storage cages, mainly including hot-dip galvanizing, zinc plating, plastic spraying, or baking paint. It can be produced according to customer requirements. The following is a detailed introduction:

A. Zinc Plating

Cold plating, which is to galvanize the surface of the warehouse cage by electroplating. The process is mainly to immerse the cage and the zinc block in the electrolyte at the same time, and pass the positive and negative of the direct current respectively. The surface of the galvanized cage in the acid electrolyte is brighter, and the surface of the galvanized cage in the alkaline electrolyte is whiter, but there is no difference between the two types of quality.

B. Hot-dip Galvanizing

This galvanizing method has a higher cost, thicker coating after galvanizing, good quality, and strong corrosion resistance. The storage cage processed by this method is suitable for occasions with relatively humid environments, cold storage, and other harsh environments.

C. Powder Coating

This method is generally customized by customers with special requirements. Electrostatic spraying is to use powder spraying equipment to spray the powder coating onto the surface of the workpiece. Under the action of static electricity, the powder will be uniformly adsorbed on the surface of the workpiece to form a powdery coating. The powder coating is cured by high-temperature baking and leveling, and becomes a final coating with different effects (different types of powder coating effects); the spraying effect of powder coating is excellent in mechanical strength, adhesion, corrosion resistance, aging resistance, etc. Due to the traditional process, the cost is also under the same effect of the painting.

Compared with the traditional process, the advantages of powder coating:

1. Efficient: Because it is a one-time film formation, it can increase productivity by 30-40%.

2. Energy-saving: reduce energy consumption by about 30%.

3. Less pollution: no organic solvent volatilization (excluding harmful gases such as toluene and xylene in paints).

4. High coating utilization rate: up to 95% or more, and the powder can be used many times after recycling.

5. Good coating film performance: The thickness of one-time film formation can reach 50-100μm, and its comprehensive indicators such as adhesion and corrosion resistance are better than the painting process.

6. Low scrap rate: before uncured, it can be re-sprayed twice.