A Letter to PET Preform customers, 3 reasons why choose metal wire cages.

time2020/12/17

- We once did a survey to our PET customers, there are mainly 3 boxes used: corrugated box, plastic box and metal box, May I know what are you using for storage PET Preforms now?

Dear Valued PET customers:

I will ask 3 questions: Are you looking for ways to decrease manual handling? Do you want to reduce to transport cost? Would you like to ensure health and safety of operation?

I think your answer should be “Yes”.

We once did a survey to our PET customers, there are mainly 3 boxes used: corrugated box, plastic box and metal box, May I know what are you using for storage PET Preforms now?

Q1: Do you want to decrease manual handling?

Metal cage with feet base design, it could easily handle by forklift truck, eliminates the need for extra wooden or plastic pallet; Meanwhile, our cages could be stackable, can up to 6 high, increase your warehouse utilization. Maybe you want to ask, corrugated boxes and the plastic box they could stack as well.

I will share a case with you from our customer, In the South Africa plant where preforms are manufactured, CCBA was having serious problems in storing, conveying, and shipping the preforms. CCBA was using cardboard cases with a volume of one cubic meter on a wood pallet.

These cases proved very problematic when stacking, they found that the bottom layers were not protected. Although there was no visible damage, it was found that these preforms were showing cracks and leaks during and after the filling process. In order to prevent this, they could not be stored more than two high. We were asked to solve the problem.

As for plastic box, they could load 5 high, but load only 200kg capacity, our metal cage could load 800kg at most.

Q2: Do you want to reduce to transport cost?

Our metal cage could be used in truck for transport, from you factory to your end customers, metal cage is more stable and durable, our customer once did a loading testing, compared with plastic bags, logistics costs reduced by 12%; plastic bags need the workers place one by one, metal cage could be loaded by one person and a forklift, importantly, there is 75% time savings, that is one crucial reason.

Q3: Would you like to ensure health and safety of operation?

Regular maintenance is essential to keep equipment safe and reliable. Lack of maintenance or inadequate maintenance can lead to dangerous situations, accidents and health problems.

There is no maintenance required for our metal cages, service life time could up to 5 years. The transportation will better vehicle fill, as well as less fuel consumption and reduce CO2 emissions.

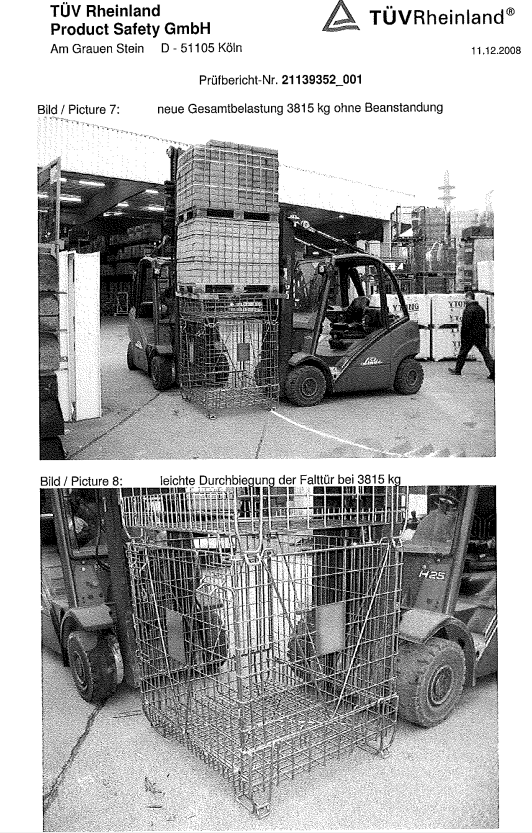

We once did TUV loading test in Germany, our cage could load 600kg, up to load 6 high.

We specialized in wire cage with more than 20 years for PET Industry, have been supplying thousands of wire cages to COCA, PEPSI, Nestle and etc.

Next article I will tell you why they choose us?

Do not hesitate to contact me to get free storage solution, I am waiting for you right here.

Best regards.