5 Essential Steps To Successful Tire Storage Project

Bulk Storage

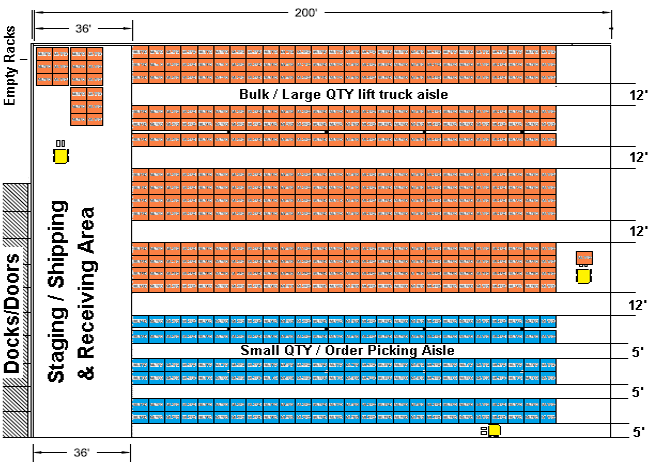

If you are storing bulk quantities of tires, you should always consider to maximize your warehouse by having your racking back to back. This will help you get the most out of your building. When the rack is empty, fold it, take it off the way and grab your tires from the one in the back or beside.

The aisles have to be at least 10 to 12 feet to allow the lift truck to circulate easily everywhere in the warehouse.

Staging Area – Shipping and receiving

Should be big enough to help you prepare your orders and also store the empty racks. We always try to keep at least 25 to 30 feet deep if possible. This is the key to save time on loading and unloading your trailers or containers.

The small quantities/SKUs/ customers’ tires

Try to avoid wasting too much floor space for these small quantities of tires. Make the aisles smaller: 4-5 feet is good. It will be easier for picking and also to get access to more tires at the same time. *Order pickers lift trucks are the best lift system for these operations.

City/fire department

Before setting up the warehouse always contact the city and fire department to see if there are any restrictions or modifications that need to be done before moving on with your tire storage project; height of the racks, sprinklers and many more. Nobody likes to be restricted to 25% of the storage capacity after signing a 5 years leasing contract so don’t forget to check prior to buying a storage system.

Layout consulting