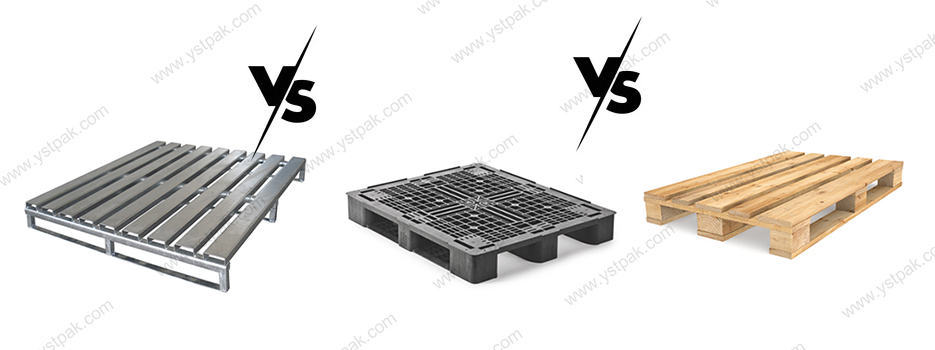

Comparison of Steel Pallet and Wooden Pallet and Plastic Pallet

publisherMandy

time2020/07/03

- Do you know the difference between steel pallets, plastic pallets and wooden pallets?

Currently, there are three types of pallets in circulation on the market: steel pallets, plastic pallets, and wooden pallets. Many customers will encounter such a problem when buying: Which pallet is better? So today we will analyze the difference between the three in five aspects.

1. Service life

The service life of the wooden pallet is short, and the turnover times are 200-300 under normal use. The service life of plastic pallets is average, which is 3-5 years. Steel pallets have a long service life, which is conventionally more than 10 years.

2. Design and production

The wooden pallets are processed using felled wood. The surface cannot be cleaned, and there will be wood chips falling off and screws corroded. Plastic pallets are produced using molds. The structure and dimensions cannot be easily changed, and the development of molds requires a certain amount of time (development cycle time is about 1 month). The design is complicated and the cost is not low. The steel tray is welded, and the specifications, load, color, etc. can be customized at will according to the actual needs of customers.

3. Raw materials

materials are the key factors that determine the load and price of wooden pallets, and the price of high-quality wood remains high, and wooden pallets are not recyclable, which causes serious loss of forest resources and environmental protection cost performance is too low. The raw materials of plastic pallets cannot be guaranteed, and there are scraps, residual materials, and recycled materials. These will cause the performance of the pallets to be insufficient, thereby causing additional losses to the enterprise. Steel pallets are produced using steel, and their own performance advantages are unmatched by the other two materials and can be recycled and reused so that resources are not wasted and 100% environmentally friendly.

4. Performance

Wooden pallets are susceptible to moisture, mold, and moths, and need to be fumigated, which increases costs and takes time and effort. Plastic pallets are weak at high and low temperatures, and cannot be used in special storage conditions, and their bending resistance is not strong. When carrying large cargoes or long loading cycles, the panel will bend significantly. The carrying capacity of steel pallets is the largest among all pallets. It has good rigidity and wears resistance. Under the spraying treatment, it can be rust and corrosion resistant, and durable.

5. Damage rate

The wooden pallet can not bear the impact, once it will be damaged The plastic pallet is formed once, and it is difficult to repair after it is damaged. Compared with wood-plastic materials, steel pallets have stronger impact resistance, are durable, and require no maintenance.

In summary, whether it is from the service life of pallets, design and production, raw materials, or from its performance, damage rate, steel pallets have greater advantages than wooden pallets and plastic pallets. As the development trend of pallets, steel pallets are recognized by more and more national alliances, including some industrial chains: food, beverage, medicine, and other industries need to be transported through metal pallets.

We are committed to creating the highest quality products and have been constantly meeting the customers' needs, if you have any demand for material handling equipment, pls feel free to contact us.

sales..........com.